Experiments with small table top presses

To comment or see existing comments, click on the title of a post and scroll down to the comment area. Write comment in the dialog box and click on Post Comment. Another dialog box will ask for your name and an email address. website URL is not necessary. Click on Comment as Guest to submit. All comments will be reviewed by site manager before approving display.

Open Press 3D Printed Mini Press

Write comment here…

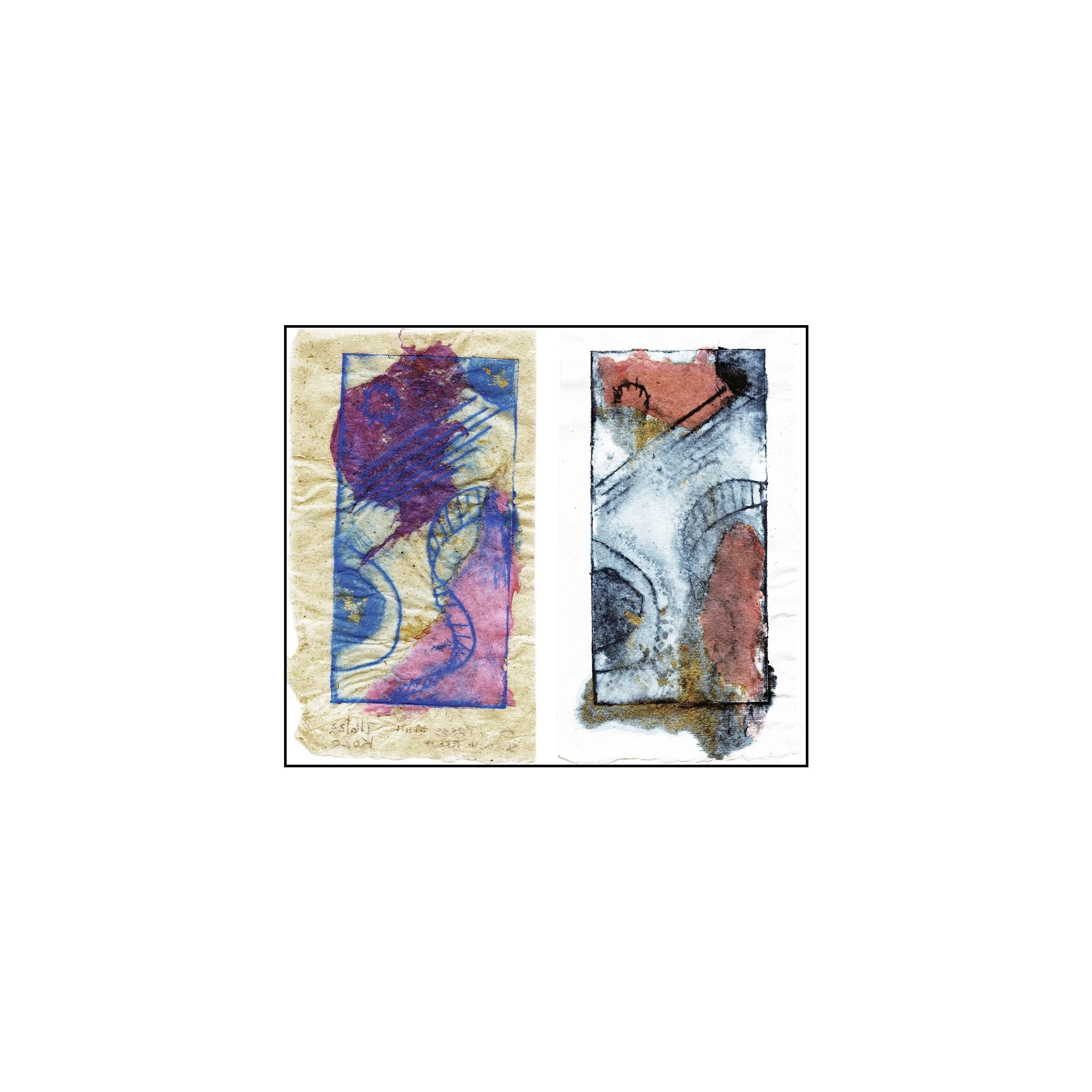

Kozo paper on left, cotton paper on right

The experimenting began with an opportunity provided by Cathy Gleason to try out an Open Press Mini Press as part of a papermaking session led by paper artist Allison Roscoe at the Manoa Heritage Center, Honolulu, HI.

The practical plate size is 100mm (4in) x 60mm (2 /38in) or smaller and 150mm (6in) x 70mm (2 3/8) largest paper size.

For this test:

Printing plate is on 2in x 4"in thin (1mm) plexiglass with both drypoint and masking tape.

Speedball Acrylic Block Printing Ink was used.

Plate was placed directly on press bed and newsprint served as a press blanket.

Hand made and hand dyed paper was chiné collection applied with methyl cellulose powder.

A light dusting of gold mica powder was randomly tapped from a fine paint brush on the surface before printing.

Assessment:

The working space was breezy and it was difficult to manage the drying time of the ink. A light mist of water was sprayed on just prior to printing. May have been overcompensation! Need to do another printing in a less breezy space.

Press is fun and easy to use but resulting prints are small.

Akua Pin Press

Kozo paper on left, cotton paper on right

This experiment began with a borrowed (thank you Marcia Pasqua at Honolulu Printmakers) Akua Pin Press.

The pin press can accommodate sheets of printing paper up to 19 1/12in wide by length of press bed used. Plate glass is recommended for smooth contact.

For this test:

Printing plate is on 2in x 4"in thin (1mm) plexiglass with both drypoint and masking tape.

Akua Intaglio Ink was used.

Print Plate was placed directly on glass press bed and felt and newsprint served as press blankets.

Dampened hand made kozo (l image) and hand made cotton (r image) paper was used.

Hand made and hand dyed paper was chiné colle applied with methyl cellulose powder.

Assessment:

The environment was more controlled and the ink is slower drying than the speedball acrylic providing more prep time.

When using the felt blanket for the cotton paper print (r) the plate slid on the glass creating a double image. Should have put a drop of water under the plexiglass printing plate for stability. Newsprint only was used for kozo (l) print and remained stable but weak ink transfer.

More practice with press “blanket” options is necessary.

However, a greater variety of print sizes are possible and pin press and plate bed do not require much storage space in small studio. Plate glass bed is delicate and a newly acquired plate was chipped on first set up!

Pasta Maker Etching Press

Kozo Paper on left, Abaca paper on right

This experiment is with an Altas Model 150mm Deluxe Pasta Roller.

The pasta roller can accommodate sheets of printing paper up to 150mm wide by practically any manageable length. There are many you tube tutorials on using pasta press for printmaking. The pasta maker had its bottom plate removed and the maker was clamped to the work table (use padding to prevent table dents) with the hand crank to the outside of the table. The maker was set to the widest setting #1. The pressure setting may be modified to account for changes in the thickness of the press pack.

I reviewed 2 artists for this investigation:

Michelle Rozic and Janet Ballweg Part 1 and Part 2

Decided to use Michelle Rozic bed and blanket approach for this test.

For this test:

Printing plate is on 2in x 4"in thin (1mm) plexiglass with both drypoint and masking tape.

Akua Intaglio Ink was used.

Press package in bottom to top stacking order was:

3 pcs Manila folder or card stock

Alignment guide template on newsprint

Sheet of acetate film

Inked plate

Printing paper

Newsprint

2 pcs Kraft Foam Sheets

Note: Be sure to stagger top foam sheets a bit on initial feed end to ensure a sheets are compressed orderly wile entering press rollers

Dampened hand made kozo (l image) and hand made abaca (r image) 4’ x 6’ paper was used.

Hand made and hand dyed paper was chiné colle applied with methyl cellulose powder.

Assessment:

The environment was more controlled and the ink is slower drying than the speedball acrylic providing more prep time.

A small drop of water put under the center of the plexiglass printing plate for stability.

Overall, the best results so far. Images are crisp and look much better on a larger sheet of paper.